The development of the CARES certification scheme for the supply and installation of Post-Tensioning (PT) systems in the UK and its acceptance by the UK PT industry played a key part in the Highways Agency lifting its moratorium on grouted post-tensioned bridges in September 1996.

As part of our global commitment to improving end-user confidence in the supply and installation of Post-Tensioning systems for concrete structures, CARES are launching a product certification scheme for the Supply and Installation of Post Tensioning Systems for Concrete Structures in Australia.

Read more...

The development of the CARES certification scheme for the supply and installation of Post-Tensioning (PT) systems in the UK and its acceptance by the UK PT industry played a key part in the Highways Agency lifting its moratorium on grouted post-tensioned bridges in September 1996.

As part of our global commitment to improving end-user confidence in the supply and installation of Post-Tensioning systems for concrete structures, CARES are launching a product certification scheme for the Supply and Installation of Post Tensioning Systems for Concrete Structures in Australia.

Read more...

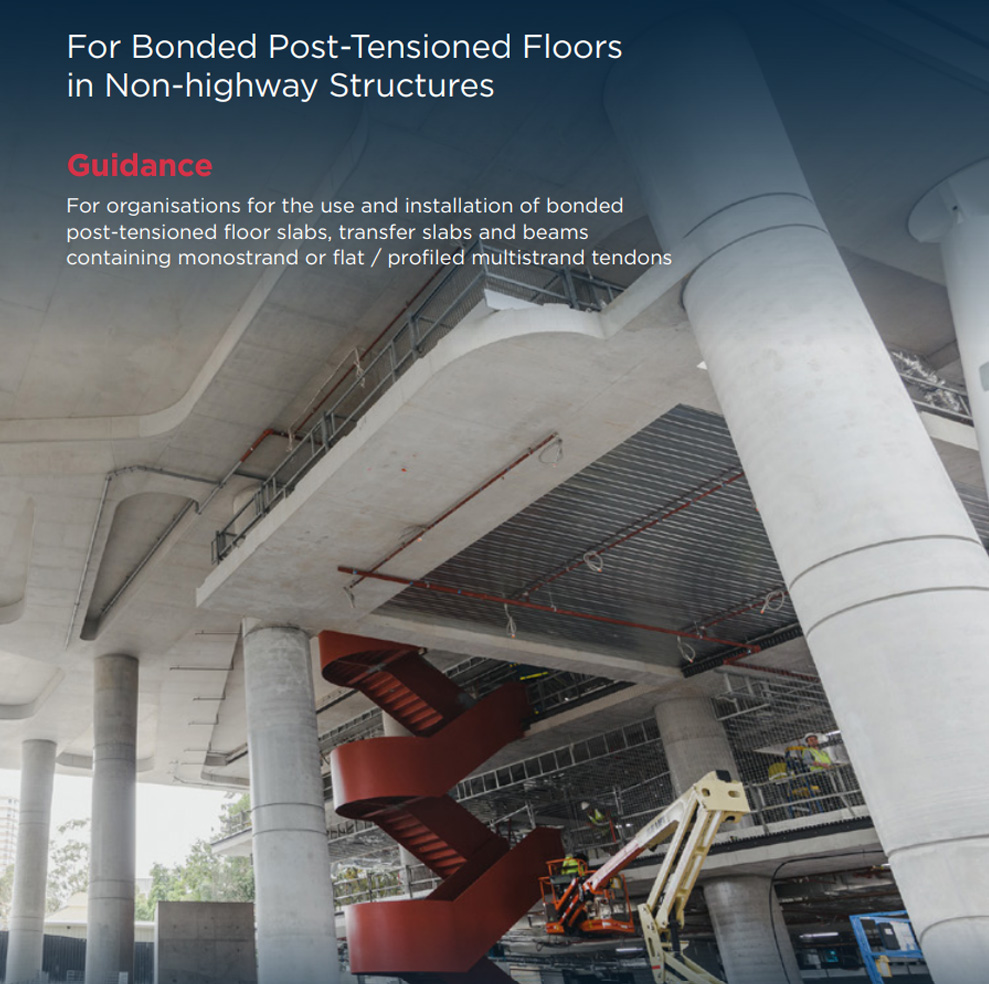

CARES Model Specification Australia For Bonded Post-Tensioned Floors in Non-Highway Structures offers guidance to organisations for the use/installation of bonded post-tensioned floor slabs and beams containing monostrand or flat multistrand tendons.

CARES Model Specification covers quality plans, health and safety requirements and material and product selection (tensile elements, anchorages, ducts and grout) and workmanship (tendon installation, pour watch, stressing and grouting) of the PT contractors.

CARES Model Specification Australia For Bonded Post-Tensioned Floors in Non-Highway Structures offers guidance to organisations for the use/installation of bonded post-tensioned floor slabs and beams containing monostrand or flat multistrand tendons.

CARES Model Specification covers quality plans, health and safety requirements and material and product selection (tensile elements, anchorages, ducts and grout) and workmanship (tendon installation, pour watch, stressing and grouting) of the PT contractors.

Strand and tensioned bar shall comply with AS/NZS 4672 and shall be obtained from Firm(s) holding a valid product conformity certificate of approval supplied by the Australasian Certification Authority for Reinforcing and Structural Steels (ACRS).

Strand and tensioned bar shall comply with AS/NZS 4672 and shall be obtained from Firm(s) holding a valid product conformity certificate of approval supplied by the Australasian Certification Authority for Reinforcing and Structural Steels (ACRS).

Anchorages for PT systems shall be adequately identified to ensure traceability and comply with the minimum performance requirements as defined in CARES APT-01 ‘Quality and Operations Schedule for the Production and Supply of Prestressing Anchorages for Post-Tensioning Systems’ and in accordance with AS/NZS 1314. The post tensioning kit may also hold an ETA against ETAG 013 or EAD 160004 but evidence shall be presented which shows that the appropriate tests have been undertaken using strand conforming to AS/NZS 4672.

Anchorages for PT systems shall be adequately identified to ensure traceability and comply with the minimum performance requirements as defined in CARES APT-01 ‘Quality and Operations Schedule for the Production and Supply of Prestressing Anchorages for Post-Tensioning Systems’ and in accordance with AS/NZS 1314. The post tensioning kit may also hold an ETA against ETAG 013 or EAD 160004 but evidence shall be presented which shows that the appropriate tests have been undertaken using strand conforming to AS/NZS 4672.

Duct and connection material shall be robust enough to resist damage during construction; for example smooth galvanised steel with a minimum wall thickness of 0.35mm, corrugated galvanised steel with a minimum wall thickness of 0.30mm or high density polyethylene or polypropylene with a minimum wall thickness of 2.0mm. Plastic ducting should conform to the requirements of fib bulletin 75.

Duct shall conform to the requirements of CARES APT-02 ‘Quality and Operations Schedule for the Production and Supply of Galvanised Metal Ducting for use in Post-Tensioning Systems’, although initial dispensation may be given providing the supplier has evidence of a Factory Production Control (FPC) certificate / Quality Management Systems certificate to ISO 9001 certified by an independent accredited Certification Body.

Duct and connection material shall be robust enough to resist damage during construction; for example smooth galvanised steel with a minimum wall thickness of 0.35mm, corrugated galvanised steel with a minimum wall thickness of 0.30mm or high density polyethylene or polypropylene with a minimum wall thickness of 2.0mm. Plastic ducting should conform to the requirements of fib bulletin 75.

Duct shall conform to the requirements of CARES APT-02 ‘Quality and Operations Schedule for the Production and Supply of Galvanised Metal Ducting for use in Post-Tensioning Systems’, although initial dispensation may be given providing the supplier has evidence of a Factory Production Control (FPC) certificate / Quality Management Systems certificate to ISO 9001 certified by an independent accredited Certification Body.

Grout suitability tests shall be carried out with materials, plant and personnel proposed for use on site at the commencement of the project, to verify the properties in Model Specification.

Where the Specialist Installer operates in sites adjacent to a project, then any grout suitability test data may be used in accordance with the restrictions as detailed in CARES APT-04 ‘Quality and Operations Schedule for the Supply and Installation Supply of Post-Tensioning Systems in Concrete Structures (excluding Highways Structures)’.

Read more...Grout suitability tests shall be carried out with materials, plant and personnel proposed for use on site at the commencement of the project, to verify the properties in Model Specification.

Where the Specialist Installer operates in sites adjacent to a project, then any grout suitability test data may be used in accordance with the restrictions as detailed in CARES APT-04 ‘Quality and Operations Schedule for the Supply and Installation Supply of Post-Tensioning Systems in Concrete Structures (excluding Highways Structures)’.

The tests shall be sufficiently in advance of grouting operations to enable adjustments to be made to the materials, plant or personnel.

Such tests shall be repeated at least every 3 months or when a significant change in conditions occurs (examples include, but not limited to change in grout supplier, water supply, significant climate change)

Grout shall consist of pre-bagged material requiring only the addition of a measured amount of water and shall be CARES approved to APT-03 ‘Quality and Operations Schedule for the Production and Supply of Prebagged Grout Material for use in Post-Tensioning Systems’

Grout shall be stored in accordance with the manufacturer’s instructions.

CARES APT-04 ‘The Supply and Installation Supply of Post-Tensioning Systems in Concrete Structures’ is for general structures such as bonded post-tensioned floor slabs and beams containing monostrand or flat multistrand tendons. This scheme allows an approved specialist producer to supply PT systems and another approved specialist to install, stress and grout the PT system.

CARES APT-04 ‘The Supply and Installation Supply of Post-Tensioning Systems in Concrete Structures’ is for general structures such as bonded post-tensioned floor slabs and beams containing monostrand or flat multistrand tendons. This scheme allows an approved specialist producer to supply PT systems and another approved specialist to install, stress and grout the PT system.

CARES APT-05 ‘Registration Scheme for Competent Post-Tensioning Personnel’ is a key part of the CARES Scheme. CARES requires PT companies to provide the training for PT supervisors and operatives and assess the effectiveness of the training. Once personnel have reached a satisfactory level, evidence of achievement is to be sent to CARES which then issues identity cards which must be worn on site. PT ID cards are issued to approved Firms for their PT personnel. Approved Firms should apply to CARES' office for the cards by submitting the application form (available from CARES office) together with a photo and PT training record for the personnel required.

Review of supervisor competence is a key component during the regular PT site audits.

CARES APT-05 ‘Registration Scheme for Competent Post-Tensioning Personnel’ is a key part of the CARES Scheme. CARES requires PT companies to provide the training for PT supervisors and operatives and assess the effectiveness of the training. Once personnel have reached a satisfactory level, evidence of achievement is to be sent to CARES which then issues identity cards which must be worn on site. PT ID cards are issued to approved Firms for their PT personnel. Approved Firms should apply to CARES' office for the cards by submitting the application form (available from CARES office) together with a photo and PT training record for the personnel required.

Review of supervisor competence is a key component during the regular PT site audits.