1. Assessment and certification system

The objective of the scheme is to give confidence to the purchaser and user of PT products and/or associated services that the product and/or service complies with the appropriate specification without the need to undertake separate verification. It involves the application of quality assurance principles to assess the supplier’s quality management systems and, as appropriate, product testing, to ensure conformity with the requirements contained in the Scheme.

The scheme will complement ongoing activities by the State and Territory governments of Australia to enhance the quality control of built structures and the transparency of supply chains thorough digitalisation and other measures.

1.1. Principles

The assessment and certification system employed in the Scheme has been developed around the following principles:

1.2. Model Specification and Quality and Operations Assessment Schedules

The Scheme’s Model Specification and Quality and Operations Assessment Schedules is shown in Table 1.

Table 1. Model Specification and Quality and Operations Assessment Schedules

|

Document |

Description |

Issue |

|

Model Spec |

Model Specification Australia for Bonded Post-Tensioned Floors in Non-Highway Structures |

2nd Edition, July 2023 |

|

APT-01 |

Quality and Operations Schedule for the Production and Supply of Prestressing Anchorages for Post-Tensioning Systems |

February 2023 |

|

APT-02 |

Quality and Operations Schedule for the Production and Supply of Galvanised Metal Ducting for use in Post-Tensioning Systems |

February 2023 |

|

APT-03 |

Quality and Operations Schedule for the Production and Supply of Prebagged Grout Material for use in Post-Tensioning Systems |

February 2023 |

|

APT-04 |

Quality and Operations Schedule for the Supply and Installation Supply of Post-Tensioning Systems in Concrete Structures (excluding Highways Structures) |

February 2023 |

|

APT-05 |

CARES Registration Scheme for Competent Post-Tensioning Personnel |

February 2023 |

1.3. Assessment

The assessment consists of:

1.4. Applicant

The applicant is required to have and be able to demonstrate:

1.5. Certification

A recommendation for approval is produced when the both office and site practice have been assessed and the Scheme criteria have been satisfied and all reported deficiencies have been addressed to the satisfaction of CARES.

The Certificate of Approval is valid for one year with renewal subject to continuing satisfactory performance. Firms granted Certificates of Approval are required to reproduce the CARES Logo, and the Certificate of Approval number on all relevant documentation.

Firms granted Certificates of Approval are required to notify CARES of all post-tension contracts on award of contract using the Notification of Contracts form. It is a condition of the granting of the Certificate that CARES shall assess:

2.

Post-tensioning supply chain

2.1. Identification and traceability system

CARES certification provides full traceability from the molten steel to the construction site by addressing all stages of production, delivery, receipt and installation into the structure and shall include the following as appropriate:

• The tendon source, majority heat number and coil/batch identities.

• The source and specification of PT anchor components (including the appropriate European Technical Approval, ETA, or CARES product certification)

• The source and specification of ducting and grout (including the appropriate CARES product certification)

• The source and specification of PT tensile elements such as strand or bar (including the appropriate ACRS product certification)

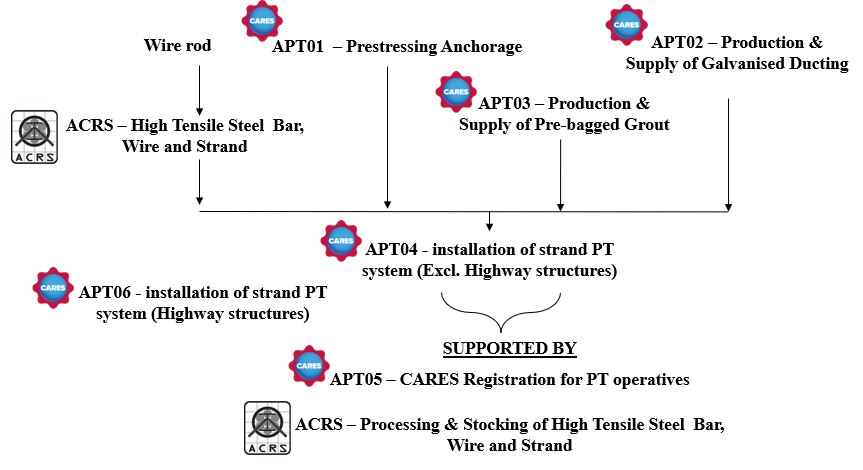

2.2. Post-tensioning supply chain – CARES approach

PT supply chain is designed to give confidence to the purchasers and is shown in Figure 1.

Figure 1. Post-tensioning supply chain